Building through the fall, winter and spring seasons can be challenging in cold climates. Sub-zero temperatures can cause irreversible damages and increase construction costs. Protect your concrete foundation walls and footings by understanding winter construction practices!

Common Foundation and Footing Failures in Winter Construction

Water freezing and expanding due to cold temperatures is the most common reason for structural failures during winter construction. These failures usually cannot be repaired and require footings and/or foundation walls be removed and replaced. Understanding how the cold temperatures affect concrete and sub-grades is equally as important on how to protect them from freezing in the first place!

What Happens When Concrete Freezes?

Concrete develops its compressive strength through the curing process when it transforms from a liquid to a solid material. The colder the temperature of concrete, the longer it takes for the concrete to harden. When it is exposed to cold temperatures before hardening, the water inside the concrete mix freezes and expands. The damage caused by early freezing is immediate and permanent. Early freezing of a concrete wall, footing, slab, or pier can reduce the compressive strength of the concrete by 30 percent!

What is Considered a Cold Weather Condition?

Cold weather conditions are in place when the ambient air temperature is below 5°C (41°F) within 4 days (96 hours) of your concrete pour. Ambient air temperature is the temperature before wind chill.

Best Practices for Placing Concrete in Cold Weather

When working in cold weather conditions, it is important the concrete is exposed to a minimum temperature of 10°C (50°F) and no more than 25°C (77°F) while being mixed and placed. These temperatures need to be maintained for 72 hours after placing. All frozen material (such as ice and snow) must be removed from forms and should never be used in concrete. Concrete should never be poured on or against any frozen surfaces. Insulated forms or blankets are typically used to protect concrete from cold weather.

Adding a high early strength additive to a concrete mix is recommended as it reduces the curing period from seven to three days.

What Happens When the Ground Freezes?

As the ground is exposed to sub-zero temperatures and cools, water within saturated earth freezes and expands. This process (known as frost heave) creates an upward or outward movement of the ground surface caused by formation of ice in soil. Heave normally occurs in the direction of least resistance and is commonly upwards. Frost heave has enough force to move objects on, or in the ground easily causing them to be out of level or plumb.

Frost Line

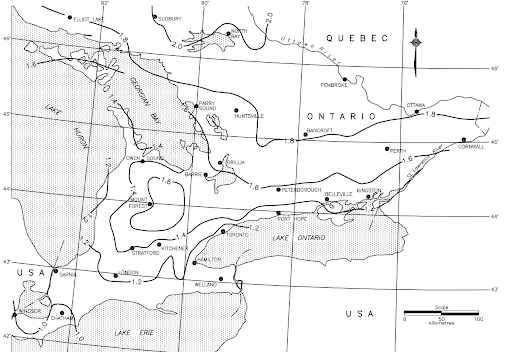

The frost line (also known as frost depth) is the total depth which the ground is expected to freeze during winter. In Ontario, this depth can vary from ~1.0 m (3’-4”) to over 2.0 m (6’-8”). The Ontario Provincial Standards has a topographic figure (below) showing approximate frost lines (in meters) for southern Ontario. Visit here for more information Ontario Provincial Standards.

How to Protect the Ground from Freezing

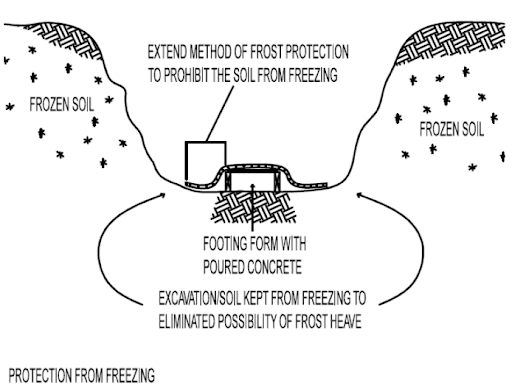

Frozen excavations can be avoided by using insulated blankets, heating and/or hay. We recommend consulting your local geotechnical engineer for the most appropriate solution for your job site.

Below is a frost protection example to prevent ground freezing. The protection is typically extended a minimum of one frost depth in either direction beyond your footings or foundation walls. It is typically maintained through the entire duration of the construction, or until the building is enclosed, backfilled and heated.

Extreme weather changes in our climate are hard to predict making it challenging to prepare for cold weather construction. When building in the fall, winter, and spring, it is imperative to keep an eye on the 3-day forecast and always make sure you are prepared for these dramatic temperature drops.

If you are ready to start your project or need construction engineering support, you should contact us at www.eternity.design.

If you enjoyed this blog post or know someone who may be interested, share it with a friend!

Have a great day!

Eternity Engineering Inc.